Linearization- A Brief Note

Let’s start with, well, how about a pixel on a chip. I’ve described it as a little light meter, making voltage corresponding to the amount of light that shines on it, actually, that’s not quite accurate. Pixels are actually more like little valves… you have to give them some current, and they actually let more or less of that current “through”, depending on how much light they see. The end result is the same, you get volts coming out corresponding to the light falling, but I wanted to clear that up so Bruce Radl and Joe Holmes could sleep at night.

The problem is, for each little light meter, we don’t get a smooth response to light across the board. Our little pixel may be very good at seeing low levels of light, and not so good at the medium levels. It may totally blow out the higher responses. The process of linearization is simply to take the response out of a device, any device, and smooth it out, make it linear. We want it to read zero at zero. If we load it with a little light, we want it to go up a little. If we feed it twice as much light, we want it to respond with a number that is double.

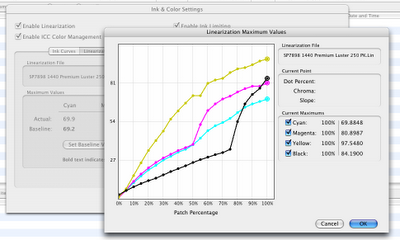

Here is a printer linearization curve, from the ColorBurst RIP. This is what Bill Atkinson was talking about… it is a map of each ink, and how it “tracks” from light to dark, with the appropriate corrections. Let’s look at the magenta graph. Magenta plays pretty well up until around 50%, but then the RIP has to boost the amount of ink dramatically to get it to be linear. I would guess from this, that if you printed out a series of neutral gray patches from the 7800 without linearization then you’d see, at middle gray, a dramatic drift to a green cast in the gray values. The linearization curve fixes this by feeding in more magenta.

Every printer is an individual device, ideally needing individual linearization, but Bill’s comment simply was saying that the printers were, first, pretty standardized (they are all pretty close to performing identically) and at that standard point, pretty linear.

Linearization is the process of smoothing out the bumps in any device. And by the way… every single pixel in the chip is going to have a different response curve. We have to linearize the readings of every single one, of thousands, of pixels on the chip to get a balanced and predictable image.

Labels: Geekzone, linearization